Equipments

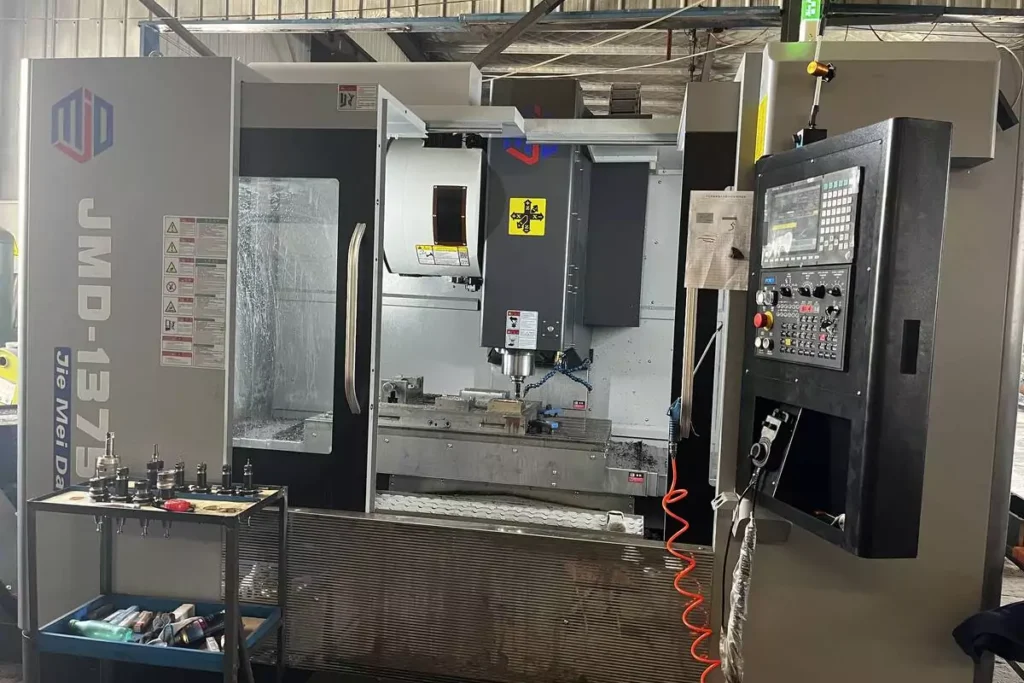

Advanced machinery for precision mold design and manufacturing services. Our in-house injection mold manufacturing facility is fully equipped with all the necessary mold making machines, including CNC Machines, Wire Cutters, Drilling Machines, EDMs, Grinders, Millers, Precision Engravers, Slow Wire Cutters, Injection machines. With this comprehensive setup, we’re able to consistently deliver more than 100 sets of mold each month.

Outstanding Support

You’ll be working with staff who are not only experienced but also certified in English. Skilled mold and injection engineers on our team, We guarantee seamless communication and expert guidance through the professional plastic injection molding manufacturing process.

Strong Production Capacity

We have injection and mold making shop in house, 21 sets injection machines which 6 sets are in dust-free room(M7 Class), assembly room and logo printing room. The largest 1100T machine could produce product weight up to 5100g.

Quality Assurance

We proudly hold several certifications, including ISO 9001, ISO 13485, ISO 14001, and ISO 45001. We adhere closely to the stringent standards set by these certifications to ensure that every stage of the injection molding manufacturing process is executed flawlessly, guaranteeing a smooth and impeccable outcome.

Why Us

Diversity in solutions

Cost optimization

Excellent in service

Reputation in business

Quality Assurance

How We Guarantee Your Mold and Injection Quality

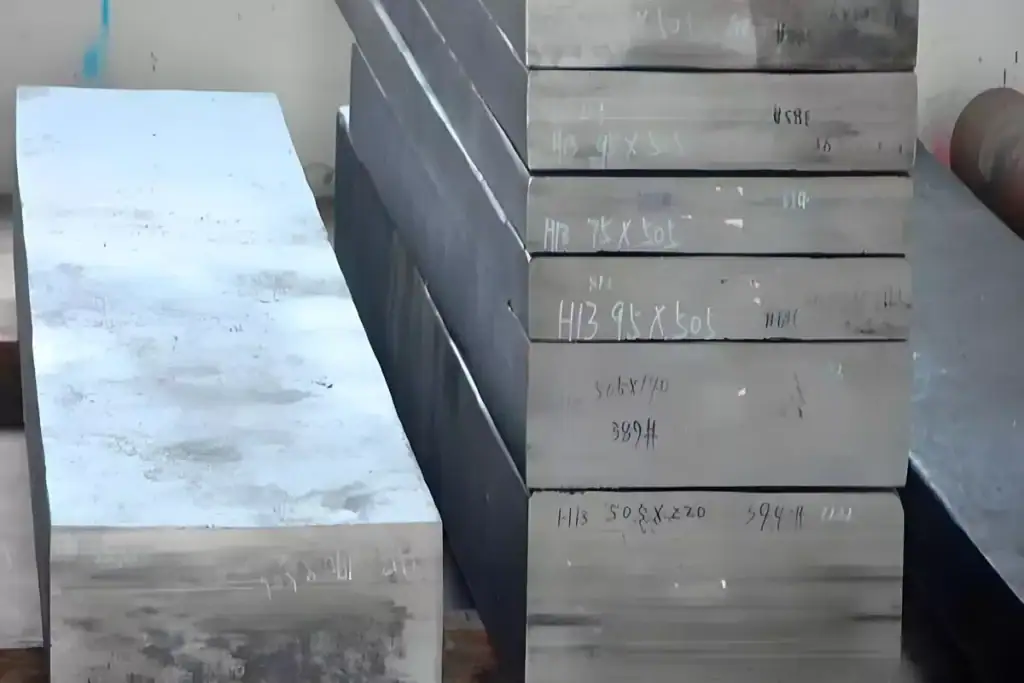

Premium Materials Only

Certified steel. Heat-treated. Traceable quality from the start.

We only use certified high-grade tool steels, fully traceable from the source. Before and after machining, all core components go through quenching and tempering to ensure hardness, toughness, and extended mold life.

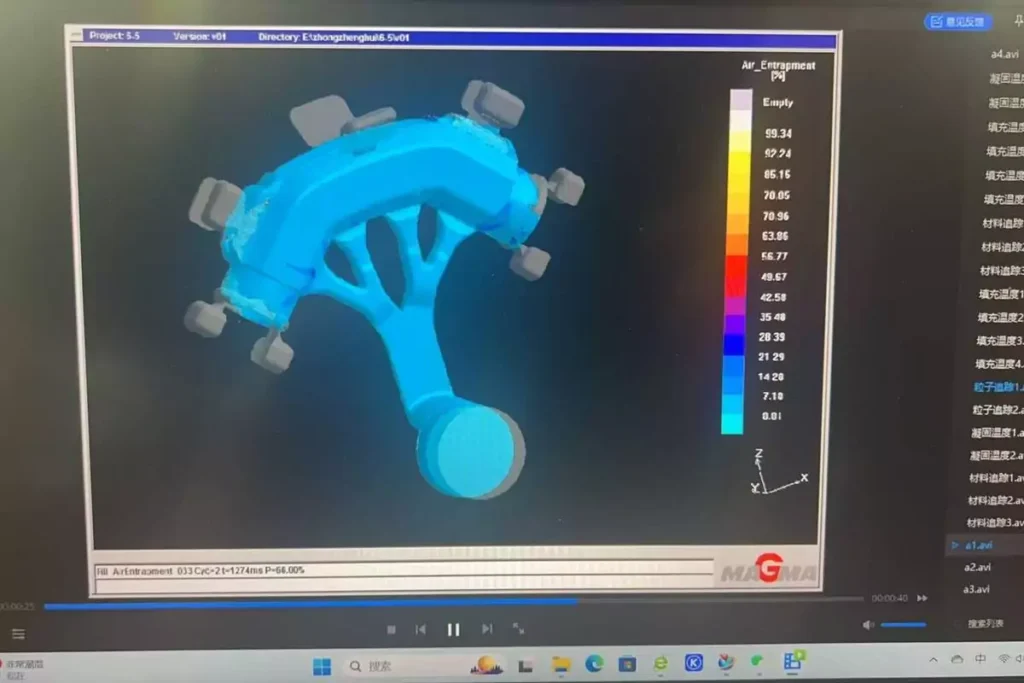

Mold Flow Simulation

Predict defects before production with MAGMAsoft® analysis.

We run MAGMAsoft® simulations before tooling starts — to predict air traps, shrinkage, and filling issues. This ensures optimal gating and venting design, helping achieve first-shot pass rates over 98% and cutting down trial-and-error time.

Precision Manufacturing

±0.01mm accuracy. Built to perform.

All key parts are machined in-house using 5-axis CNC, EDM, and wire cutting.

We implement cavity segmentation, part coding, and dimensional tracking to maintain ±0.01 mm tolerance, even across complex or multi-cavity tools.

Comprehensive Quality Checks

Inspected at every step — from steel to sample.

Strict QC is applied throughout the entire process: incoming steel, in-process checks, full CMM measurement, assembly inspection, and mold trial evaluation.

We provide full inspection reports, sample measurements, and trial photos/videos upon request.

Protected & Tracked

Secure shipping. Lifetime traceability.

All molds are rust-proofed, sealed with desiccant, vacuum-packed if needed, and delivered in custom export-grade wooden crates.

Each mold is labeled with a unique ID and production history, making future maintenance or upgrades easy and traceable.

Plastic Injection Safe Shipping

Multiple protections, clear information.

Plastic products come with various protective measures and labels such as packaging boxes, woven bags, protective films, and shipping marks. They are waterproof, moisture-proof, and resistant to damage, ensuring clear order informations and timely delivery with quality and quantity guaranteed.